ERP software solution for steel service centres & the metal trade

unitop – the holistic solution for your industry.

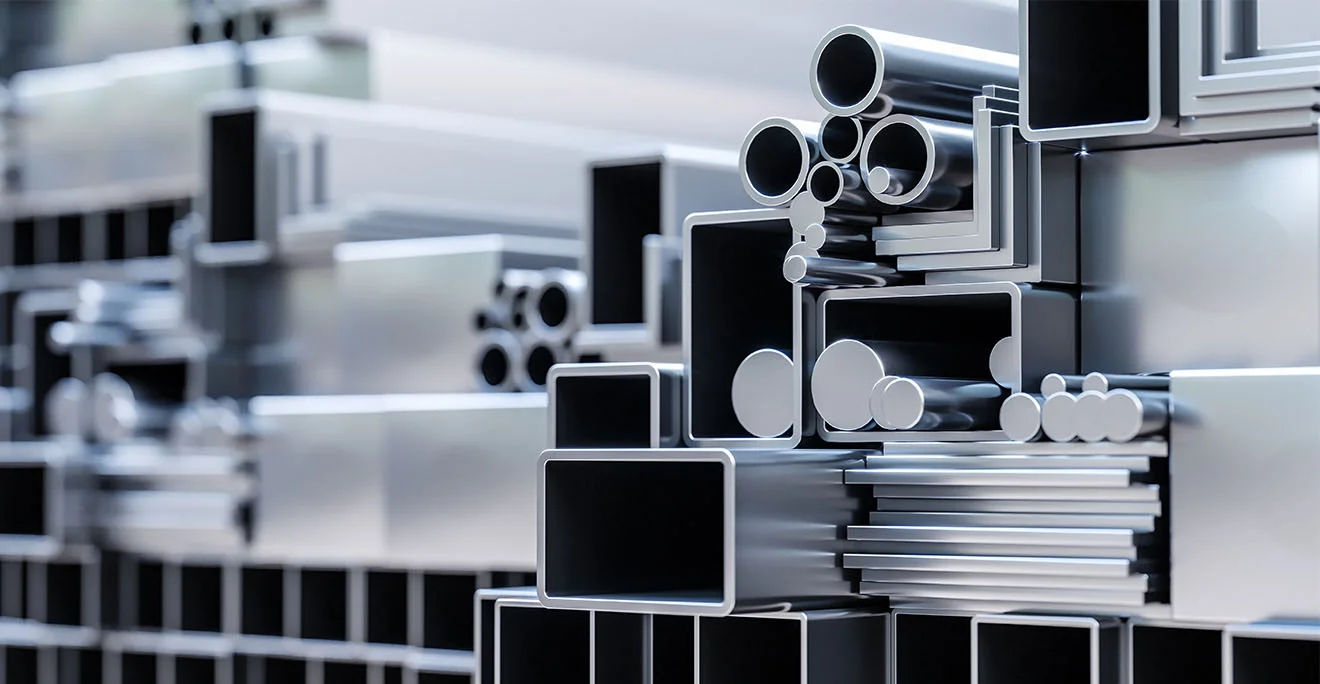

Are you in the metal trade or operating a steel service centre? Are you looking for a way of controlling your business processes digitally and efficiently? From procuring materials, storage and batch management to slitting, cross-cutting, contract manufacturing and despatch – with unitop on the Microsoft Dynamics 365 Business Central platform, you can manage all your processes and procedures centrally within a single system. Our solution helps you manage and process steel coils, slit strips, thin sheets, round steel, flat steel and other commercially available semi-finished products. You can also seamlessly integrate residual quantities management and scrap management, price calculation by weight or dimension, optimised coil slitting to minimise scrap, certificate management and connected weighing scales and machinery. This means that you can keep a close eye on stocks, material flows and commercial processes at all times.

Developed using sector-specific competence & Microsoft expertise

unitop – an ERP software solution for the metal trade & steel service centres

With over 25 years of project experience in the metal trade and in steel service centres, we have a precise knowledge of the specific challenges and procedures in your sector. unitop was developed in close collaboration with our customers and with experts from the sector and is continually being developed in line with current practices to reflect the latest market requirements as effectively as possible.

As a Microsoft Solutions Partner for business applications, we champion technological ingenuity, scalability and long-term security of investment. With unitop, you can experience the advantage of an ERP solution that seamlessly integrates all of your processes on a single, future-proof platform – from procuring materials and warehousing, batch management, certificate management, slitting, cross-cutting, contract manufacturing and managing residual quantities to logistics, calculating prices and digital communication with customers.

Key requirements for ERP software for the metal trade

In the metal trade, efficient materials management, transparent inventory management and flexible pricing models are crucial for your business success. Using a single ERP solution that displays all of the common processes in the sector, from goods inward through to despatch, ensures transparency, speed of processing and the highest degree of compliance:

Key requirements for ERP software for steel service centres

As a steel service centre, you specialise in slitting coils and strips in line with the customer’s requirements and in processing cross-cutting and cutting to size in the most effective possible way. For that reason, your choice of ERP system not only should provide the best possible support for your material flows and production processes, but should also allow machinery and optimisation to be connected and generate comprehensive quality documentation:

Sector-specific functions in unitop

ERP solution for the metal trade & steel service – its main functions at a glance

unitop in action

Actual sector-specific examples from the metal trade & steel service centres

The typical requirements in the metal trade and in steel service centres can be controlled efficiently in unitop. Below, we will provide you with a brief explanation about how our end-to-end solution can help you, on a practical level, to configure your specific processes in the most efficient possible way:

From purchasing and warehousing semi-finished goods to despatch, with unitop, you can digitalise the entire process. Communication via EDI and digital certificate transfer ensure quality and traceability at all times. In addition, high-rack warehouses and mobile MDC devices support flexible warehouse logistics, whilst customer-specific packaging instructions can be stored on the system and issued automatically.

Whether you are slitting (longitudinal cutting) or cross-cutting steel coils and strips or cutting sheet metal to size: with unitop, you can control and document all processing steps – from reserving the material to reporting completion. Batch management and certificate management are fully integrated within that process. To make the most effective possible use of materials, you can connect your nesting software (for cutting to size) or optimisation software (for scrap-optimised coil slitting). You can also transmit all processing parameters to machines such as saws, cutters and laser tables digitally.

unitop makes managing profiles and individual dimensions easier: with the help of profile codes and pre-established input screens, you can capture not only customary lengths but also special variants particularly quickly and accurately. From the coil to the finished tube, the material used remains fully and transparently traceable at all times. That way, you are always in full control at every step of the production process.

Using our product configurator add-on, you can assign suitable raw materials correctly in unitop and initiate the necessary processing steps to produce bespoke final products for your customer from within the software solution itself. This not only saves you time and processing costs, but it also avoids sources of error within the work process. Order details are copied across directly for the product labels and weight information from connected weighing scales is automatically passed into the system.

What our customers say

Innovating. Transforming. Succeeding.

We provide comprehensive support — from process analysis and the appropriate unitop licensing to implementation and ongoing operation on the Microsoft platform.

Contact

Are you looking for individual advice or do you want to find out more about our ERP solution? Get in touch with us – we’ll be pleased to advise you.