ERP software solution for the metal processing sector

unitop – the holistic solution for your industry.

Are you in the metal processing business? Are you looking for an efficient way of digitalising your production and quality processes, from work preparation, pre-machining and production to assembly and despatch? unitop, our ERP software solution, operates on the Microsoft Dynamics 365 Business Central platform and contains expansions specifically developed for the sector. You can use it to control the full range of metal processing procedures centrally and continuously – from material availability, work planning, chipping, sheet processing and assembly to despatch and batch tracking. The solution also provides a convenient way of managing materials, test certificates, the specifications and requirements in the relevant standards, and technical drawings.

Developed using sector-specific competence & Microsoft expertise

unitop – our ERP software solution for the metal processing industry

With over 25 years of experience in the metal sector, we have a precise knowledge of the challenges and procedures used by our customers in the metal processing industry. unitop was developed in close collaboration with companies in the industry and is continually being improved to reflect current practices and to fulfil the latest processes and requirements in the most effective possible way.

As a Microsoft Solutions Partner for business applications, we champion technological ingenuity, scalability and long-term security of investment. With unitop, you can experience the advantage of a solution that seamlessly integrates the full range of processes from work preparation and materials management to production, quality assurance and logistics – on a single, future-proof platform.

Sector-specific functions in unitop

Our ERP solution for the metal processing industry – its main functions at a glance

DMS, EDI & MDC

Additional central functions for your metal processing procedures

In addition to providing core, industry-specific functions, unitop also provides some additional powerful functions to make your processes even more efficient and transparent:

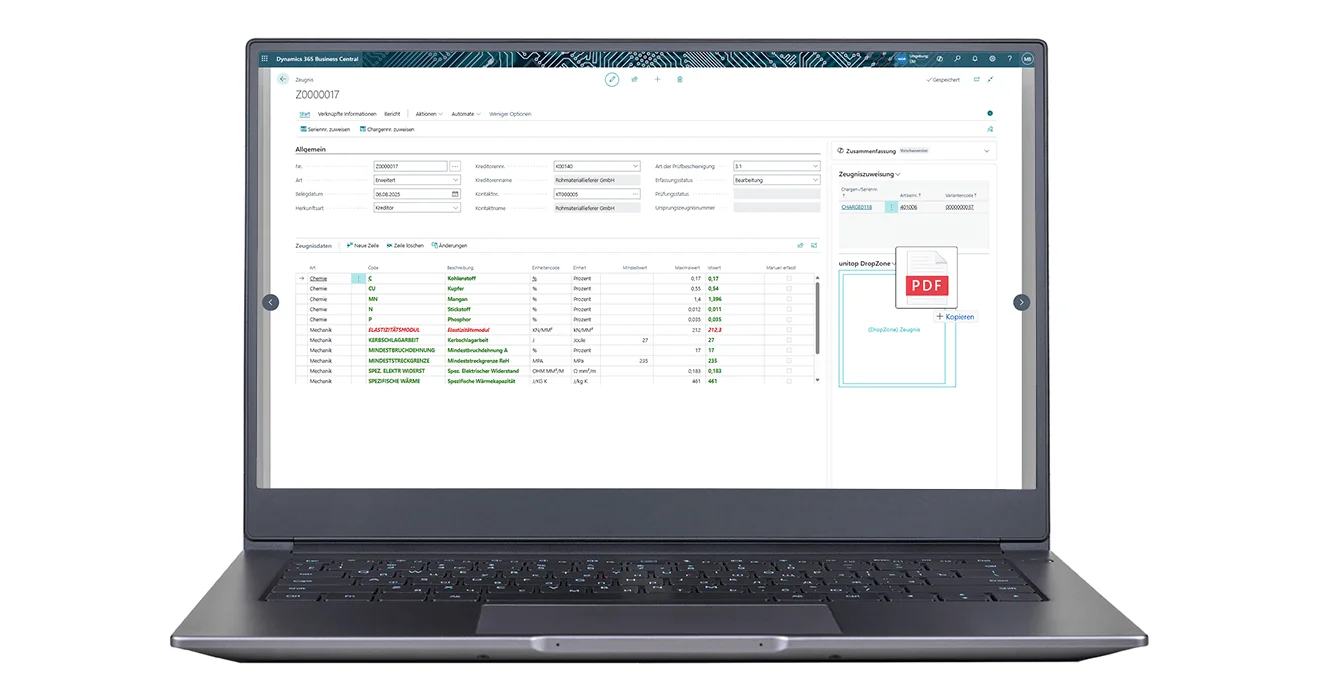

Digitally manage your production documentation & test certificates

Thanks to unitop’s on-board DMS, all documents typically used in the sector are archived directly within the ERP system. Whether these take the form of factory certificates, test certificates, acceptance test certificates (e.g. in accordance with DIN EN 10204:2005-01), material certificates, order and delivery documents or correspondence ‒ all documents are stored digitally, linked to the individual processes concerned and are available in a secure form for auditing purposes at any time. That way, all documents regarding materials tracking, quality assurance and traceability are constantly in view and structured in the most effective possible way to support audits and inspections.

Data sharing via EDI for metal processing

unitop allows electronic data to be shared automatically (via EDI) in a way that specifically meets the requirements of the metal processing industry. Master data are transmitted between your company, your customers and your suppliers. This facilitates communication, speeds up supply processes and ensures transparency throughout the entire value creation chain.

Mobile data capture in warehouse, production & assembly

With unitop, you can capture all movements of goods, stock transfers and production feedback directly at the machine, at the storage location or in the despatch area – using a scanner or a mobile app. That way, stocks, production orders and batch movements are always up to date and you can ensure that all procedures in the metal processing industry are fully traceable.

What our customers say

Innovating. Transforming. Succeeding.

We provide comprehensive support — from process analysis and the appropriate unitop licensing to implementation and ongoing operation on the Microsoft platform.

Contact

Would you like to know how unitop can provide the best possible support for your processes? We’ll be pleased to advise you.