ERP software solution for series production

unitop – the end-to-end solution for your industry.

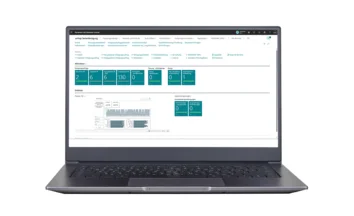

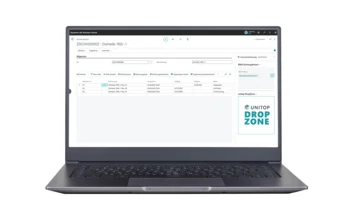

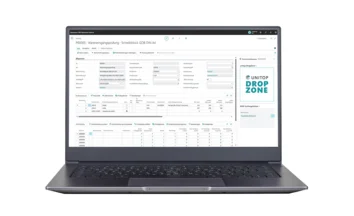

Are you involved in series production and are you looking for an end-to-end solution that controls your processes just in sequence (JIS)? From checking availability to delivery: with unitop, you can display call-offs, Kanban and JIT/JIS in an integrated way. Our business solution is based on Microsoft Dynamics 365 Business Central and brings together resource allocation, detailed planning, shopfloor feedback, quality assurance, logistics and despatch. Your production certificates and test protocols are stored in an audit-proof way in the integrated DMS and JIT/JIS documents are clearly version-controlled at all times. Scanners, label printers and additional devices on the internal network can be securely connected using the unitop HUB. In the role centre, your sales and marketing and customer service departments will have an overview of call-offs, deliveries, complaints and framework agreements at all times.

Developed using sector-specific competence & Microsoft expertise

unitop – our end-to-end ERP solution for the series production sector

Fluctuating call-offs, tight sequence times, standardised variants and stringent accountability requirements: we have a detailed knowledge of the challenges you face in the series production industry. Based on many years of project experience and our in-depth expertise in the sector, we have developed an end-to-end ERP solution that displays your usual processes from start to finish.

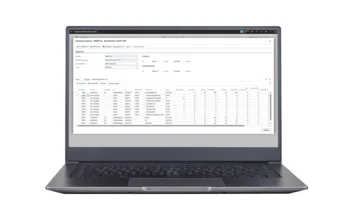

As a Microsoft Solutions Partner for business applications, we champion technological ingenuity, scalability and long-term security of investment. From work preparation and materials management to just-in-sequence (JIS) production, quality assurance and EDI-assisted document processing: With unitop, you benefit from a solution that seamlessly integrates your processes – on a future-proof Microsoft platform.

Sector-specific functions in unitop

Our ERP solution for the series production sector – its main functions at a glance

DMS, EDI, MDC & BI

Additional key functionalities for your series production processes

Alongside the core, sector-specific functions, unitop also provides some powerful, additional functionalities to make your processes even more transparent and efficient:

Using the integrated DMS, you can archive your factory and test certificates, acceptance records, material certificates, order and delivery documentation and correspondence directly in unitop. All documents can be linked to processes and stored securely in an audit-proof way.

With unitop, documents and master data information can be shared with customers and suppliers automatically – shortening processing times, reducing errors and ensuring transparency during planning, procurement and despatch.

Movements of goods, transfers and production feedback can be captured directly in the production hall and the warehouse – by mobile app or scanner. Stocks, orders and batch transfers are kept up to date and full traceability is guaranteed at all times.

Key performance data on line performance, adherence to deadlines and stock turnover are available in real time. Threshold values and notifications assist you in your day-to-day control; by selecting detailed views, you can switch from a key performance indicator to the underlying entries or series numbers.

Innovating. Transforming. Succeeding.

We provide comprehensive support — from process analysis and the appropriate unitop licensing to implementation and ongoing operation on the Microsoft platform.