ERP software solution for the plastics industry

unitop – the holistic business solution for plastics producers & variant manufacturers

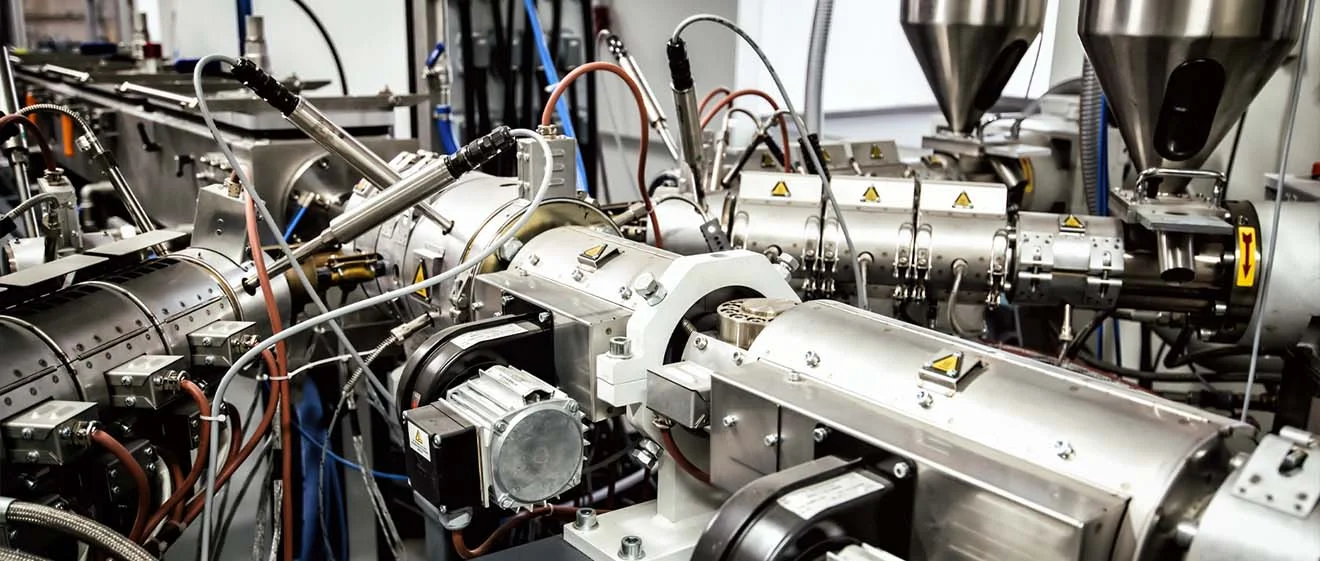

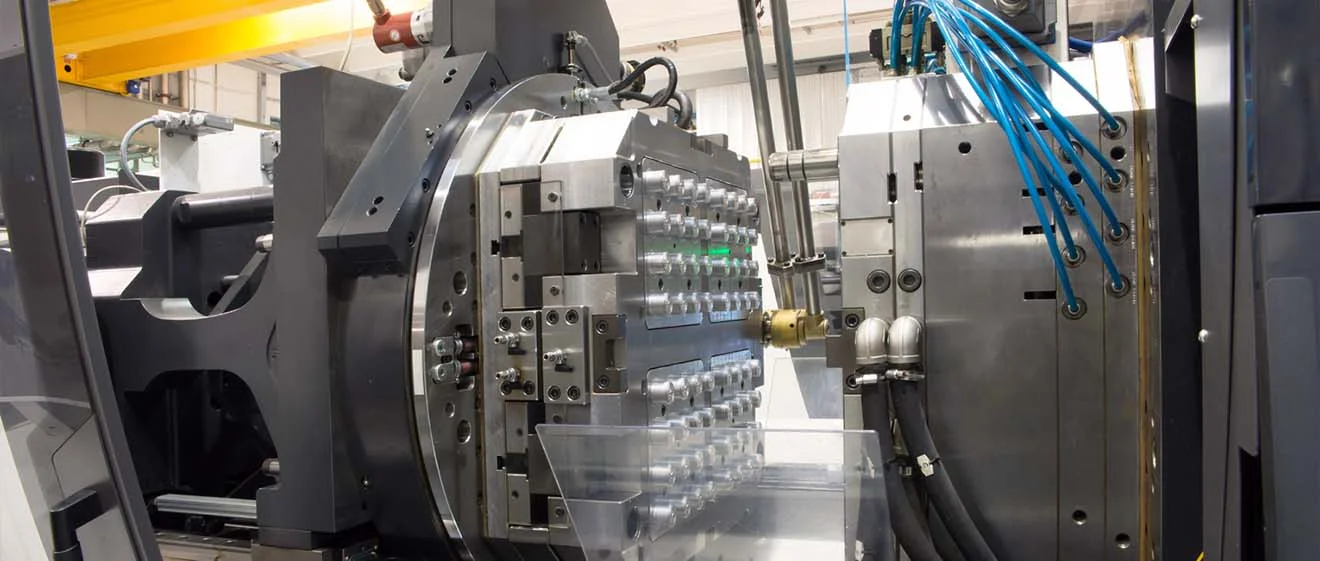

Are you active in the plastics industry and looking for an ERP system capable of supporting your processes in the best possible way? Whether injection-moulding or extrusion, with unitop, you can control all of your processes centrally, efficiently and transparently. The solution operates on the Microsoft Dynamics 365 Business Central platform and reliably reflects the typical demands that exist in the plastics processing industry.

Digitalising small & medium-sized enterprises

unitop – our ERP software solution for the plastics industry

For more than 25 years now, we have been helping small and medium-sized enterprises turn their digital transformation ideas into reality, bringing together our many years of sector-specific know-how with our certified Microsoft expertise.

As a recognised Microsoft Solutions Partner for business applications, our unitop solution provides you with a future-proof, end-to-end ERP solution that includes a wide variety of sector-specific expansions.

Whether you need it for production, quality assurance, logistics or document management, with unitop, you can control all of the processes typically involved in the plastics processing industry both centrally and efficiently within a single system.

Making technologies usable

unitop – our ERP software solution for manufacturers in the plastics industry

Take advantage of a solution that simplifies and speeds up your processes:

Innovating. Transforming. Succeeding.

Smart ERP functions for the plastics processing industry

Our end-to-end solution includes expansions specifically developed for the sector that help you control and manage all the different processes in your company in the most effective possible way. For example, they not only provide you with a great deal of flexibility when planning new injection-moulded components, but they also enable you to retain full control of your production orders at any time – from the initial configuration right through to despatch.

DMS, EDI & MDC

Your plastics production & processes in full control

Whether you are looking to generate material certificates, production documents, delivery forecasts or stock movements, unitop puts powerful functions at your fingertips to support the processes typically found in the plastics industry.

DMS for plastics certificates, test reports & quality certificates

Using the integrated DMS in unitop, all of the documents commonly used in the sector can be directly and securely archived in the ERP system for auditing purposes. There, you can digitally store your material certificates, test reports, RoHS certificates and suppliers’ certificates and link them to the processes concerned. That way, you can access all the documents you need for material tracking, quality assurance and traceability purposes at any time, leaving you well prepared for any audits or when responding to customer enquiries.

Data sharing via EDI

With unitop, you can share data efficiently and accurately. Typical business processes such as orders (ORDERS), delivery forecasts (DELFOR), despatch advices (DESADV) and invoices (INVOIC) are processed with customers and suppliers in standardised form. Automated communications of this type make your processes faster, keep sources of error to a minimum and ensure transparent processes throughout the supply chain as a whole.

Mobile data capture in warehouse, production & despatch

Capture production confirmations directly on your injection moulding or extrusion systems. In storage locations and despatch departments, mobile devices make data capture both quick and easy.

Driving your digital transformation.

Additional ERP functions to ensure optimum control of your plastic production processes

From calculating the precise quantity to performing the CO₂e calculation, our end-to-end ERP solution helps you by providing a wide variety of functions to configure your plastics production process more transparently, more efficiently and in a more focused way.

Thanks to the BI dashboards, all relevant production-related and quality-related key performance data, such as quantities produced and reject rates, are clearly displayed and you can monitor them at any time.

With unitop, you can manage individual pricing and discount conditions for products such as granulates or additives, clearly and transparently.

Centrally controlling multiple factories and production sites helps you retain a continuous overview and significantly reduces your administrative burden.

Save focused packaging specifications and controlled storage conditions in the system to ensure that material and product properties are also adhered to while in storage and during despatch.

Get the most out of the integrated monitoring functionality in Business Central to analyse energy and material consumption in real time. That way, you can gain clear insights into costs, identify peaks in consumption in good time, compare different sites and continually optimise production.

Capture and comprehensively document the carbon footprint of your production process to provide clear evidence of sustainability and fulfil internal and external requirements.

What our customers say

Innovating. Transforming. Succeeding.

We provide comprehensive support — from process analysis and the appropriate unitop licensing to implementation and ongoing operation on the Microsoft platform.

Contact

As our end-to-end solution, unitop reliably displays the processes that typically arise in the plastics processing industry, especially in injection-moulding and extrusion. Do you use other production processes? If so, we will be happy to help you display your specific processes digitally. Get in touch with us and we will be pleased to advise you individually on a peer-to-peer basis.