An ERP software solution for foundries

unitop – the holistic solution for your industry.

Are you in the foundry business? Are you looking for an efficient way of digitally displaying your processes, from melt planning, casting and mould production to test reports and despatch? With unitop based on the Microsoft Dynamics 365 Business Central platform, you can manage and document all of the relevant business processes in your foundry centrally in a single system – from raw materials procurement, melt management, model management, casting, fettling and quality assurance to comprehensive batch tracking and distribution. All relevant test certificates, material data, and specifications and requirements under the relevant standards are captured in digital format and can be quickly retrieved.

Developed using sector-specific competence & Microsoft expertise

unitop – an end-to-end ERP solution for foundries

With over 25 years of experience in the metal sector, we already have a very precise knowledge of the specific requirements and processes that exist in a foundry. Our unitop solution was developed in close collaboration with foundry experts and during many projects carried out in practice. It is also continually being optimised and enhanced to ensure that it reflects the latest regulatory and process-related requirements as effectively as possible. As a Microsoft Solutions Partner for business applications, we champion technological ingenuity, scalability and long-term security of investment. From pre-calculation and final costing, melt preparation, model and mould management, casting and fettling to test reporting, certificate management and logistics ‒ with unitop, you can benefit from a solution that brings together all of your processes on a single, future-proof platform.

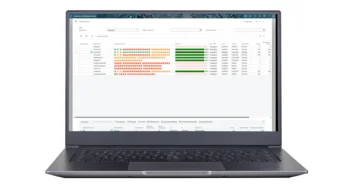

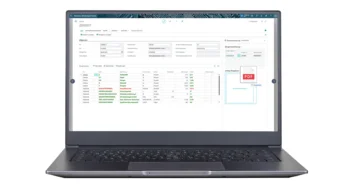

Sector-specific functions in unitop

Our ERP solution for the foundry industry – its main functions at a glance

Maximum transparency & efficiency

Key functionality areas for your foundry processes

Alongside the sector-specific core functions, unitop also supports you by providing additional, powerful expansions:

DMS, EDI & MDC

Manage your test certificates, material certificates & melt protocols digitally

unitop’s on-board DMS archives all relevant documents directly within the ERP system. Whether those documents are factory certificates, test statements, melt protocols, heat treatment process diagrams, material certificates, order and delivery documents or correspondence, all documents are stored away digitally and securely for auditing purposes and are linked to the relevant processes, to ensure comprehensive chains of evidence, quality assurance and audits.

Share data via EDI for foundry technology

Whether they involve details of batches, test certificates, material data or order confirmations, our unitop solution automatically allows you to share data electronically (via EDI) with your customers and suppliers. That streamlines communications and creates greater transparency throughout the supply chain as a whole.

Mobile data capture in the foundry and quality assurance

Capture all movements of goods, inventory transfers, melts and production updates directly at the furnace, in the warehouse or in the despatch department, using a mobile app or scanner. That way, batch and test movements will remain up to date and will be easily trackable at all times.

What our customers say

Innovating. Transforming. Succeeding.

We provide comprehensive support — from process analysis and the appropriate unitop licensing to implementation and ongoing operation on the Microsoft platform.

Contact

Would you like to know how unitop can provide the best possible support for the processes in your foundry? We’ll be pleased to advise you.